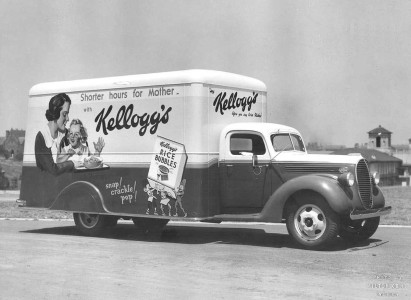

Following Kellogg’s recent plan to optimize its supply chain infrastructure as part of a four-year plan to save up to $475 million a year by 2018, let’s review and look at how they’ve been handling supply chain issues ever since they started.

Kelloggs Supply Chain Process - From Factory to Supermarket Shelves

Kellogg’s: An Introduction

Kellogg’s is one of the leading companies in providing food items (especially breakfast items and convenience food) to its customers located worldwide. The company was established in 1906 in USA and till now, it’s been following the philosophy of ‘improved diet and improved health’. As the world's leading cereal manufacturer, not only has Kellogg’s been serving its customers at a national level, it has also been able to successfully establish a worldwide network globally.

Since 1938, Kellogg’s has opened manufacturing plants in United Kingdom, Australia, Canada, and Asia. Kellogg’s’ products are now manufactured in 19 countries and are sold in approximately 160 countries. It produces about 40 different types of cereals and snacks, such as Kellogg's Corn Flakes, Rice Krispies, Special K, Fruit n' Fibre, as well as the Nutri-Grain cereal bars.

Supply Chain Sectors

A business’ supply chain involves a chain of all activities, from product development to delivering the final product to the customer. Kellogg’s has been following a socially responsible stance at all levels of its supply chain.

At Kellogg’s, there are certain processes that are undertaken in its supply chain management system, and these activities make sure that the product manufactured is made available to its ultimate consumer. The supply chain has been divided into three sectors by the industry:

Primary Sector:

This is where the raw material is provided to the company from around the world.

Secondary Sector:

This is where the products are made using the raw material supplied and shipped to wholesalers or stored in warehouses.

Tertiary Sector:

This is a service sector that companies in the secondary sectors use to optimize or benefit business processes.

Different departments and functions coordinate and work together throughout the supply chain system, including purchasing, quality check, sales, transportation and distribution processes. It is part of the business strategy of any business to consider how they would get raw material from the best available source and how that raw material would be used to manufacture a product.

As Kellogg’s is involved in food items business, it falls under the category of secondary sector. It is important for the company to get the best available material and make sure that the product is of standard quality. Much more care is required in maintaining the supply chain for food items businesses and it is necessary that products are stored and transported effectively without incurring any loss in the quality of the product.

Kellogg’s: A Secondary Sector Business

Kellogg’s possesses an organized and well equipped transportation and storage system to ensure the products do not spoil and reach customer in fine quality. They follow the lean production system (also known as Toyota production system or Just-In-Time production) to streamline processes and eliminate waste. Kellogg Planning System (KPS), a large-scale linear program, is used for operations, production, inventory and distribution system.

It helps the company in optimizing production and inventory costs and budgeting.As determined above, Kellogg's is a secondary sector business. It obtains its raw materials of wheat, corn, cocoa, rice and sugar from primary suppliers around the world. These materials help make over 40 different breakfast cereals and snacks to sell to customers through the tertiary sector. It is a large-scale manufacturer and stores sufficient stocks to meet customer orders.

Large-scale manufacturers like Kellogg's need to consider many different aspects of their operations:

- Where to locate the business

This could be near to the materials' suppliers. For example, power stations are often sited near to coal sources to reduce delivery costs. Frozen peas factories may be near farms to ensure the product is fresh. Kellogg's ingredients are grown in many countries. It is more important for its manufacturing sites to be near to distribution channels and customers so products can reach shelves quickly.

- Size and scale

They need large factories with adequate space for equipment and production processes. They also need to accommodate the frequent delivery of incoming materials and outgoing finished goods.

- Where and how materials and finished goods are to be stored until needed for sale

As part of its manufacturing process, Kellogg's packages products ready for immediate distribution.

- Where its customers are

Kellogg's does not sell its breakfast cereals directly to consumers. It uses intermediaries like wholesalers, supermarkets, high street stores and hotels. Transportation and storage processes occur between all stages of the supply chain.

For example, Kellogg's largest UK production plant is at Trafford Park in Manchester. Initially, one of its storage depots was 15 miles away at Warrington, however, Kellogg's moved this storage to a new warehouse site in Trafford Park, only one mile away from its production base. This provides specialist energy-efficient warehousing of stock 24 hours a day.

Just-In-Time Inventory Management Technique

Having the right supply chain management mix ensures businesses have the right product, in the right place, at the right time. Kellogg's manufactures the right products based on their research into consumer needs. It manages the distribution channels to place its products in stores. Its focus on cost-effective systems ensures its prices remain competitive. It works with retailers to improve promotion of its products. But what about inventory management?

Usually, businesses tend to keep inventory levels high so as to meet uncertain and quick demands of its customers. However, keeping high inventory is always costly for them. This is why many retailers want to hold limited stocks of products to reduce warehousing costs.

This is why Kellogg's uses a system called Just-In-Time to provide an efficient stock inventory system. Just-In-Time means that just enough products are made to fulfill orders and limited stock is kept. Thus, it is imperative that Kellogg's gets the balance right at each section of the supply chain. Late deliveries or the failure to deliver due to a lack of products may make retailers buy from competitors. Furthermore, Kellogg’s also aims to reduce lead time to preempt uncertain customer demands and control excessive costs.

Kellogg’s Collaborations In The Tertiary Sector

Kellogg’s has major relationships in the tertiary sector of its supply chain. These include the major retail supermarkets such as Tesco and ASDA and some in the wholesale sector such as Makro. Kellogg’s relies on retailers to help it foster a good relationship between the consumer and its products.

To drive sales, Kellogg’s is involved in initiatives that help add value for retailers. An example of this is the Shelf Ready Unit that Kellogg’s developed with Tesco. This displays Kellogg’s products easily and effectively. This means that the supermarket uses less staff time (and cost) in setting up a display. The display is attractive and makes it easier for consumers to choose from, increasing turnover for both Kellogg’s and Tesco.

Kellogg's employs specialist transportation and storage companies to be responsible for all the logistics aspects of its business. To improve its distribution, Kellogg's collaborates with TDG, a logistics specialist. TDG stores and transports pallets of Kellogg’s cereals. This reduces transport costs considerably and allows Kellogg’s to concentrate on its specialized area of manufacturing cereals and other food products.

Kellogg's also shares transportation with another manufacturer, Kimberly Clark. This has reduced distribution costs, and helped keep Kellogg's products competitive. The system helps lower the number of partly-full or empty vehicles on the road. This saves time, road miles, and provides additional environmental benefits of reducing CO2 emissions.

Employing Technology For Efficient Distribution & Restocking

Through its collaborations with TDG, Kellogg's now has a more efficient distribution system. Computerized stock-holding systems ensure shelves are always full and orders are delivered on time. TDG keeps the warehouse costs low through computerized heating and specialist transportation skills.

The computerized stockholding shows immediately when shelves are empty. It then automatically sends orders to a Kellogg’s manufacturing base to replenish stocks, minimizing waste and increasing Kellogg's profits. This also enables the company to offer competitive prices, which makes for happy and loyal customers. Kellogg's can keep stocks levels to a minimum, and allow customers like ASDA and Tesco to reduce their stocks and storage costs too.

These tactics illustrate the effectiveness of Kellogg's supply chain management, as one that is achieved by numerous collaborations with supply chain industries. Each company works within their specialist area to provide products and services to business customers and also, end consumers.

Kellogg’s lean production system streamlines processes and eliminates waste. Computerized warehousing means that products are manufactured efficiently, and transported straight from the warehouse to retail customers, avoiding any delays for customers.

Conclusion

A peek at Kellogg’s operations and processes show that the three sections of the industrial supply chain need to interact to ensure goods or services reach consumers efficiently.

The efficient delivery of the product to the consumer at the right price, in the right place and at the right time, will result in good business for each link of the chain. This takes strategic planning and effective collaboration with all partners.

The company's collaboration with firms like TDG and Kimberly Clark, for logistics, and FDF, for environmental performance, has helped the company to build long-lasting relationships to value the end consumer.

Partnering with industry specialists benefits the business, the customer, and the environment, and shows how specialization has made Kellogg's supply chain management more cost-effective and socially responsible.