Work in process (WIP) inventory, also called work in progress inventory, is crucial for creating an accurate balance sheet, as it represents the value of goods at all stages of the manufacturing process before completion. Using this guide and our work in process calculator, you can quickly and effectively work out your WIP inventory.

What Is Work in Process Inventory and How to Calculate it

What is a Work in Process Inventory?

WIP inventories are goods or products in the intermediate stages of the production process. It represents the value of materials, labour, and overhead costs that you’ve already spent but haven’t finished transforming into the end product.

In manufacturing and production, products will likely go through several stages before reaching the final finished goods stage. WIP inventory includes partly finished items that are being actively worked on or are awaiting more processing. This inventory category exists between raw materials inventory and finished goods inventory.

Discover more about calculating finished goods.

WIP inventory is crucial for businesses that engage in production or manufacturing, as it represents the investment in the production process.

QuickBooks Work in Process Calculator

Using our work in process inventory calculator will automate your calculations. You simply need to input your beginning WIP inventory, manufacturing costs, and your completion percentage. After adding these to the calculator, you’ll receive your WIP inventory number.

Work in Process Inventory Formula

Here is a general formula for calculating your work in process inventory.

WIP Inventory = Beginning WIP Inventory + Manufacturing Costs - Cost of Goods Completed

If you use the first-in, first-out (FIFO) accounting method, you must assign costs depending on the order in which materials or units are added to production. Use the following formula:

WIP Inventory = Cost of Beginning WIP Inventory + Cost of Units Started or Transferred In - Cost of Completed Units

How to Calculate Work in Process Inventory

Calculating work in process inventory is straightforward. You must determine the value of your partially finished goods in the manufacturing line. The method you need to use varies depending on your business’s accounting system.

Here is a basic WIP calculation:

- Identify the direct costs of the production process. These costs typically include direct materials, direct labour, and manufacturing overheads.

- Determine the equivalent production units for each cost component. Equivalent units represent the partially completed units in terms of fully completed units. This step involves accounting for the completion percentage for each cost component.

- Allocate the direct costs to the equivalent production units. For each cost component, like direct materials, direct labour, and manufacturing overhead, you must multiply the cost per unit by the equivalent units for that component.

- Add up the costs of each component to calculate the total cost of the WIP inventory. This total represents the value of partially completed goods in your production line.

The specific formulas and calculations may differ depending on the accounting method your company uses, such as the weighted average method or the FIFO method. Ensure you double-check your accounting process before using this step-by-step guide.

How QuickBooks Can Help

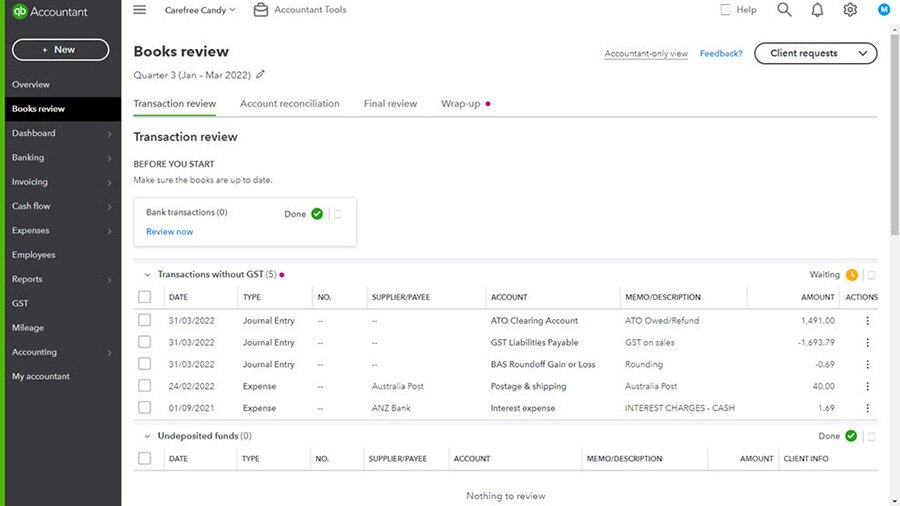

Accurately calculating WIP inventory allows businesses to report their financial position and reflect on the value of inventory at various stages of completion. Using QuickBooks Online expense management software, businesses can record and track the costs of their WIP inventory by entering direct material costs, direct labour costs, and manufacturing overhead costs.

QuickBooks inventory management software also allows you to generate customised reports to analyse your WIP inventory. You can create reports summarising WIP inventory costs, quantities, and values. This helps you monitor the progress of WIP items, identify bottlenecks in the production process, and make data-driven decisions about your inventory.

Ready to automate your WIP inventory calculations? Sign-up for QuickBooks Online Plus today or start your 30-day free trial and take control of your inventory management.

Frequently Asked Questions

Looking for something else?

TAKE A NO-COMMITMENT TEST DRIVE

Your free 30-day trial awaits

Our customers save an average of 9 hours per week with QuickBooks invoicing*

By entering your email, you are agree to our Terms and acknowledge our Privacy Statement.