How to Implement Lean

The first and biggest hurdle for many in the manufacturing business is to reevaluate what they view as waste. Typically in the manufacturing world, waste is the label given to leftover scraps or unusable or defective products. While these are two of the areas of waste identified in a lean system, you need to recognize that the idea of waste encompasses much more.

One way to readjust your perception of waste is to focus on the specific steps that can be implemented to achieve a lean system. These steps typically are:

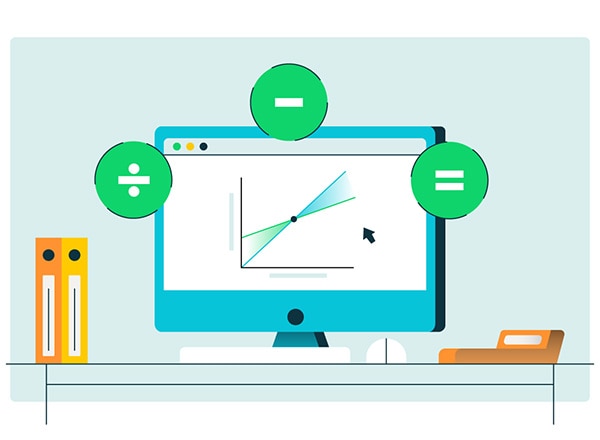

1. Design a Simple Manufacturing System

One of the tenets of a simpler system is the need to only use and handle product or materials when they are needed. This decreases the amount of inventory you need to keep on hand, increases productivity since workers are not juggling more product than they need and increases your process efficiency. If you can’t design a new one from scratch, you can also reassess your current system to make it simpler.

2. There Is Always Room for Improvement

This means that “good enough” must be stricken from your vocabulary. Remember that anything that doesn’t add value to the customer—not the product—should be labeled as waste and be eliminated or reduced. Chances are that there are always steps in the process that can be eliminated to reduce waste.

3. Improve the System Continuously

A mindset that values continuous improvement and innovation is essential to making the lean system work. By constantly evaluating and reevaluating internal and external processes and procedures, organizations can make large and small improvements in a variety of ways that will ultimately impact their bottom line.

While these three steps may seem (pardon the pun) simple, actually adhering to them is the easiest way to think and go lean.