Just-in-time (JIT) inventory management is an approach to managing a business’s inventory so that whatever materials and supplies are required for the production process are received only when they are needed — just in time.

In this article, we explore everything you need to know about JIT inventory management, including:

- What JIT is

- How JIT works

- Examples of JIT

- Industries that typically use JIT inventory management

- Why JIT is important

- The advantages and disadvantages of JIT

- Why a business should consider transitioning to JIT inventory management

- What makes JIT different from economic order quantity

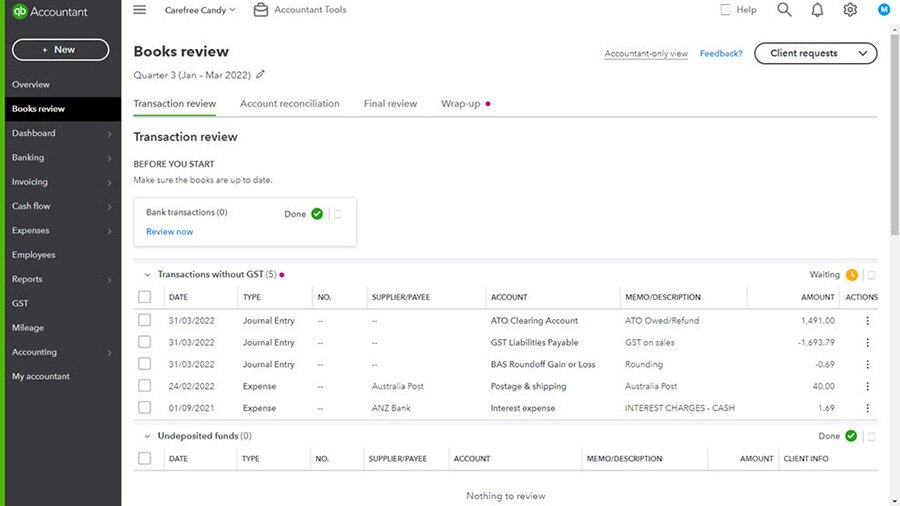

- How QuickBooks can help you manage JIT inventory to lower costs and boost productivity

- FAQs

While JIT inventory management can deliver significant benefits and is embraced by several industry sectors, it is important to ensure that the overriding principles of this approach match the unique requirements of your business and sector to maximise its positive impact.

Let’s dig in.