Five steps to better inventory management on your construction projects

Step 1: Change your mindset and embrace inventory management

Historically, inventory management has not been part of the construction industry’s language. In fact, the JIT model precludes inventory management because materials are expensed at the time of purchase. While a convenient practice, it also hinders accurate job costing and reporting.

Nowogrodzki explained: “As construction companies grow, it’s to their benefit to stop relying on third-party suppliers for materials in the just-in-time model. Consider a small contractor with a renovation job. The contractor purchases materials upfront, which creates a large expense before even billing for work. This problem is fixed when contractors take control of inventory—buying and storing materials upfront and then expensing them when used. This now provides proper tracking of inventory and supports extremely accurate job costing and reporting.”

For this reason, a change in mindset is required. The time has come for the construction trade to view itself as an inventory-management-driven industry in order to manage a more agile enterprise.

Step 2: Develop a resilient (rather than efficient) supply chain

An extension of the tip above, this step is about managing supply chains toward resilience versus efficiency (as with JIT). This includes building inventory, securing critical materials and long-lead items, and identifying alternative suppliers. Building a 'back-up' network of vendors will better protect businesses in times of crisis.

This can also include increasing off-site construction by identifying vendors to manufacture prefabricated components in controlled environments. This is a good alternative to onsite production and can be more cost effective. A few examples of standard prefabricated assemblies include steel sections, concrete, walls, and roof trusses.

Step 3: Bulk up your workforce

Labor shortages have long been a pain point in the construction industry. The pandemic placed even more strain on an already stretched-thin labor market. As such, shoring up your labor market is recommended. Planning initiatives for building up your workforce can include:

- Identify alternative sources for labor: Look beyond traditional recruitment efforts to safeguard against shortages. Ask for referrals within your existing workforce, regularly review specialized job online job boards, and use construction temp agencies and search engines.

- Invest in training: Well-trained employees tend to be more in tune with their role and expectations. A regular training regimen promotes consistency, which fosters higher levels of security and job satisfaction.

- Provide regular, positive feedback: People do want to be managed, and providing consistent input is part of good management. When employees understand their strengths and weaknesses, it helps them improve and become even more of an asset to the company.

- Engage in best practices: Adhering to industry best practices not only helps with overall efficiency and profitability, but also enables businesses to proactively identify areas for improvement to continually enhance workplace conditions, and by extension, employee morale.

Step 4: Adopt new and safer ways of working

A strong focus on safety has many positive outcomes, starting with making employees feel like they are important to the organization. Employees who feel valued by the company are more inclined to follow safety procedures, which leads to fewer accidents and injuries while also boosting productivity.

Consider also providing employees with the proper personal protective equipment required to perform their duties safely and confidently while on the job site. Taking proper safety measures will help to retain workers longer term.

“Keeping your people safe should be a top priority,” said Nowogrodzki.

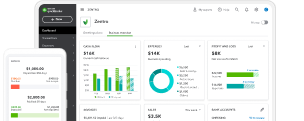

Step 5: Automate inventory management

Automating inventory management is the key to heightened efficiency and eliminating time-consuming manual tasks within an inventory-driven industry like construction. Processes within the vertical, from small renovation to large-scale construction, are complex. Contractors deal with an array of construction materials (from raw materials and consumables to prefabricated products) and are often managing multiple construction sites at any given time.

As such, the need to automate inventory counts and inventory transactions, as well as manage storage locations, work orders, and purchase orders using a powerful and streamlined inventory management system, is critical. The ability to do so adds up to immense time savings, higher profit margins, and a fortified bottom line.

Automation begins by adopting the right technologies, starting with advanced inventory management software that can seamlessly integrate with your accounting system. The ability to automatically sync data (critical functionality) between solutions better positions construction professionals for proper asset tracking, job costing and reporting, and management of inventory overall.