Best practices for VMI

Once you’ve decided to introduce VMI to your business, ensure that you apply the following practices.

Build strong relationships with your vendors

This cannot be overstated. VMI success begins with strong trust between the parties as critical business information is shared. A win-win relationship is key as is an understanding that both parties play equally important roles.

Set up a comprehensive VMI agreement

The devil in the details. Without a comprehensive understanding of the role and responsibilities of each party, and clear plans around risk and change management, the early euphoria around a new partnership can wane, leaving a mess in its wake.

Set goals and KPIs to measure success

Every business is unique even when products on offer look similar. Every business will have unique goals and metrics to measure success. The parties should ideally discuss these ideas and have a clear plan as to individual and joint goals and the corresponding KPIs so that both parties can arrive at a mutually agreed definition of success.

Maintain clear communication

VMI is not a set-it-and-forget-it business model. There should be clear channels of communication agreed on as well as systems and processes established for how records or exchanges are managed.

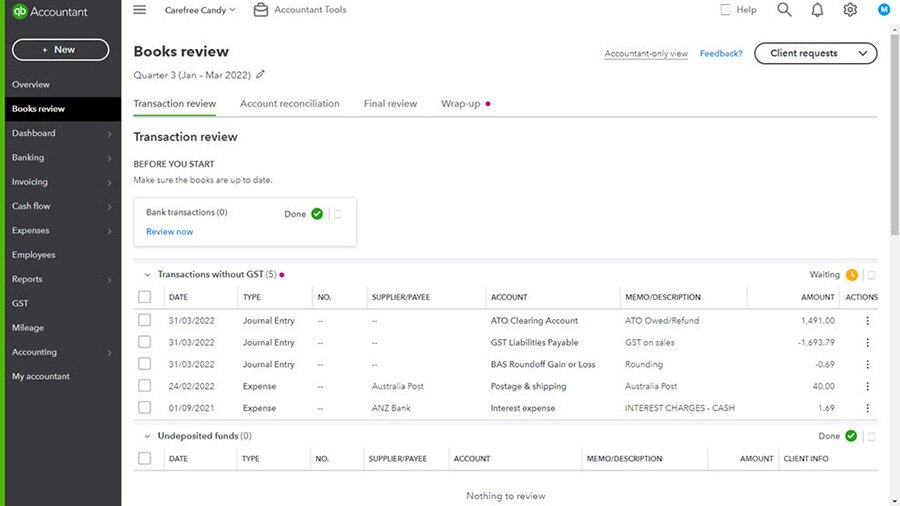

Inventory management software such as QuickBooks can generate custom reports that enable the parties to gain insights into inventory performance, thus supporting informed decision-making.

Use VMI software

So here’s where we are. You understand what VMI is, and how it works, and you believe in the advantages it brings. After reviewing the pros and cons, you’re now ready to move ahead. This is the point to consider whether technology can play a useful role in supporting your move.

QuickBooks Online can help streamline VMI through its inventory management feature.