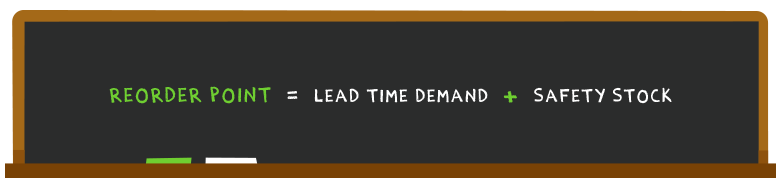

First, let’s define all the components that make up this equation by looking at a reorder point example calculation.

Components of the reorder equation

Average daily sales or usage

Average daily sales is the average number of units sold or used per day over a defined period. Three months or 90 days is a good starting increment to use. A retailer would measure the average number of units sold, while a manufacturer would calculate the average number of components used per day.

Let’s say you sold:

- 40 units of an item in March

- 60 in April, and

- 46 in May.

Over those three months (or 92 days), an average of 1.5 units were sold daily.

Average delivery lead time

Average delivery lead time is the average time it takes for a shipment to arrive from when the order was placed. Average delivery lead time changes with fluctuations in seasonal demand, the quantity ordered, and distance from the up-chain supplier.

For a reasonable measure, take an average of the past three months of POs for the SKU item you want to set a reorder point for. If your sales cycle is longer or shorter, adjust accordingly.

Safety stock

Safety stock is the amount of inventory a business holds to mitigate the risk of shortages or stockouts. The safety stock calculation is the difference between the maximum daily sales/usage and lead time and the average daily usage and lead time.