Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

I don't think it matters but I'm running QB Premier Manufacturing and Wholesale 2018

I have created an Inventory Assembly and I've been building assembling in QB for many years but what I've never been able to figure out is how to let QB tell me what parts I need to order if I want to build more assemblies than what I have in current inventory.

As soon as I enter a quantity that is greater than I can build I just get a pop up window saying I can't build that many and I have to scroll through the list and compare the Qty Needed column against the Qty On-Hand column. The problem with this is that you don't know how many parts are on each line item because some line items could need 1 item per build or you could need 20 parts for that line item.

Surely there's a way to generate a report that says if you want to build 500 of this assembly you'll need to order this many more of these parts.

Hi @GeorgeIoak,

You have 2 options whenever you get the error message "Not enough components on hand".

As for the report that tells you which assembly item(s) needs to be reordered, you can run the Inventory Reorder Report by Vendor.

Here's how:

In the report, you can check the Order column. Any inventory item that has a check on it means you need to reorder them. See the screenshot below for an example of this report.

At the moment, there isn't a report that allows you to enter a certain number of assemblies and then show you how many items are required. I can see how this feature can be useful to our users, and with that, we have taken note of this idea.

Speaking of inventory, you can take a look at this article to learn how you can edit the quantity or the total value of products: Adjust your inventory quantity or value in QuickBooks Desktop.

Let me know if you have additional queries. Post a comment below, and I'll get back to you.

Thank you @Ryan_M for providing some information about my question.

Thanks again

Thanks for the prompt response, @GeorgeIoak.

When you say pending order, did you use a purchase order to record this one? If so, you can delete the transaction to omit it from your reports.

However, if this is a built assembly marked as pending, follow these steps to remove it.

The report provided by my colleague is for you to know which of the inventory items has a shortage. Use the Assembly shortage by item report to show the items and subassemblies you need to complete all pending build assemblies.

Here’s how to run the report:

Take a look at this article for the details: Customize reports in QuickBooks Desktop.

From there, you can also automatically create purchase orders for the deficit items. Let me show you how:

I’m adding these articles for more information about creating an assembly: Combine your inventory items to build finished goods and Track the products you manufacture.

Please let me know if you have additional concerns. I’m always here to help. Have a good one!

Hi @KhimG

Sorry, to clarify, I meant that I do not have an order but was asked what the lead time would be for an order of 500 assemblies. The earlier reply mentioned entering a pending build assembly and then running the reorder report. I was a bit nervous about entering a pending build assembly when I'm not even sure if I'll get that order or what the order quantity would be. From what you said I don't need to worry about doing that because it is easy to delete the pending build and I assume that this would not have any negative impact.

I do not see a "Assembly Shortage by Item" Report but this sounds more like what I am looking for so hopefully that report is available in my version of QB and I can experiment with it to see if it would accomplish what I want.

Thank you for reaching back out, @GeorgeIoak.

I’m happy to help you with a pending build assembly. You can un-build certain items as in editing the Quantity from the build assembly. This way, the components are returned and stock automatically.

Here's how:

@KhimG provided steps above as well to go through the whole process.

Let me guide you on how to view the Assembly Shortage by Item Report:

This article includes steps regarding reports:

Here’s a couple of articles that other customers have found helpful:

Should you have other questions, feel free to come back to the Community.

I ran through your steps for the Assembly Shortage Report but that appears to just show the assemblies and not what I actually need to order for a potential/pending build.

Hello there, @GeorgeIoak. I'm here to help you get the report that you're needing.

For stock items used in assemblies to be ordered from suppliers, you can create a sales order using the stock assembly. After that's been created, run a custom report to show the details. Here's how to begin:

An invoice can now be created from the sales order for the assembly that was built.

You're almost there! Now you can run a report to show the items used in the assemblies. I've provided the steps below:

You also have the following options:

This will get you the proper report. Here's an article with additional information on how to customize item reports.

If you have any further questions or concerns, I'll be here to help. Have a great day.

Thanks for the information but this again is not working as expected. All I want to do is run a report that answers the question "If I want to build 500 of these assemblies what parts do I need to order"

I really don't see the answer to this question with the reports you have had me look at and if the information is there it is buried in hundreds of other components that are in my items.

In Khim G's post it says to select the "edit" button at the top and then "delete build". If only there were such a thing! Where is it? I have no "Edit" button or "Delete Build" and I SO wish I did. I'm using the 2021 Enterprise Platinum edition. My problem is an incorrect Assembly Build which needs to go away...forever.

Where IS this Edit button or Delete Build?

Hello there, @dkb-Bigfork.

To remove the assembly as suggested by my colleague @KhimG, you'll need first to open the pending Assembly you built. Once it's open, click the Edit menu at the top, then Delete Build.

For your visual reference, see the below screenshot:

You can also check out this article for more information: Track the products you manufacture.

If there's anything else you need, feel free to comment down below. I'll be right here to help. Have a great day.

Why doesn't the "Assembly" or "Group" Item show me how many of the group I have available?

They show 0 quantity - so now I can't sell them on my website that synchs my POS inventory!

Good evening, @Kristin Arvidson.

Thanks for chiming in on this thread. Let's work together to get this problem handled.

Before digging further into your issue, can you provide me with a screenshot of the information you're describing?

This will help determine the best solution for your business. I'll be just around the corner when you're ready!

Screenshots below:

POS shows 0 quantity for my "Test Assembly" and for the "Groups" I set up - even though I have plenty of the components that make up the set.

So - my website that synchs to POS thinks I have no Group to sell.

I appreciate you getting back to us about your assemble concern, Kristin.

I'd like to see the screenshots you're referring to, but it looks like they weren't uploaded successfully. If you can attach them again, it will be greatly appreciated.

Also, can you please tell me if this happened before or is this the first time it happened? For now, I have some recommendations to make sure your assemblies have the correct quantity.

First, make sure the quantities are assigned when you create the assembly. Even if you added the components, you also need to add the quantity of the assemblies. See these screenshots:

If you can't edit it anymore, adjust the quantity manually. For the complete steps, see this link: Adjust your inventory quantity or value in QuickBooks.

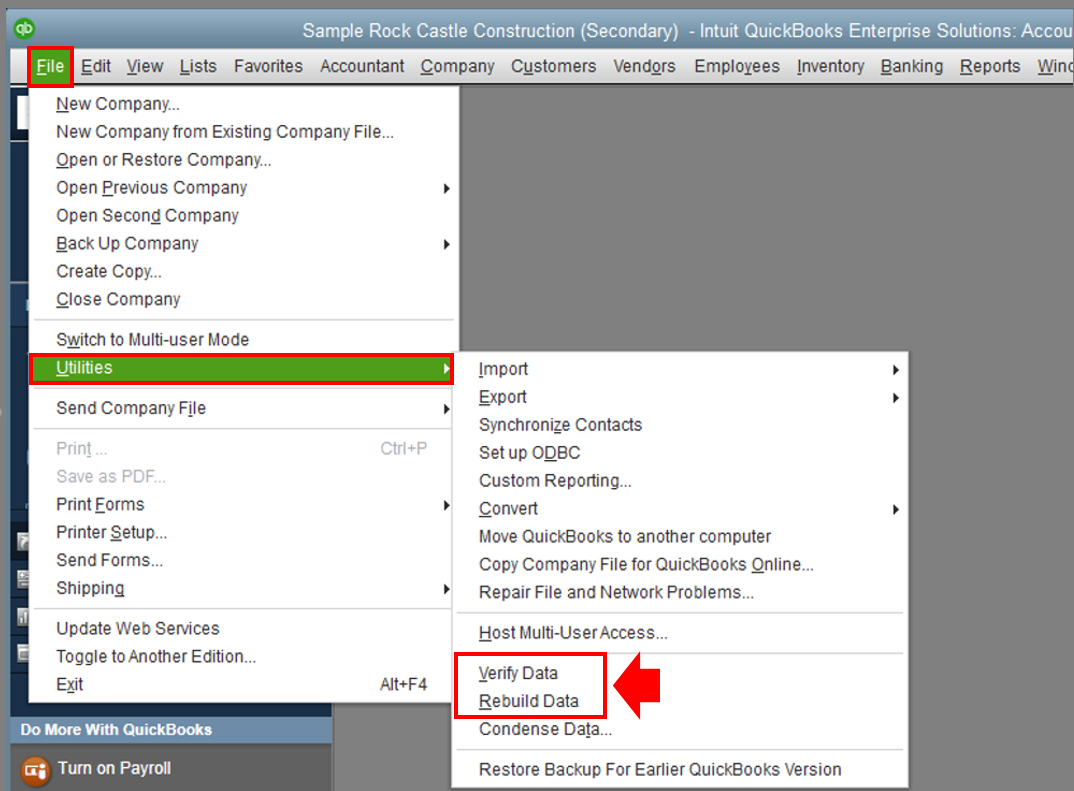

If you have assigned the quantities and you're still getting 0 quantity, run the Verify/Rebuild Utility. This will help diagnose and self-fix data issues in QuickBooks Desktop. Here's how to do that in QuickBooks:

Kindly update this thread for the additional details and updates of this assembly concern. I want to ensure everything is working well for you, and I'm here to provide further assistance and insights. Have a great day!

Hello - to clarify, I'm using QB point of sale (Not quickbooks financial)

This is the first I'm trying to set up Assemblies or Groups, so I don't know if this usually happens. I'm trying to figure out which type of item is the best option.

I would need QB POS to tell me how much of a Group I have available to sell by looking at how much quantity available there is of each component. This will be a ever-changing number as I receive and sell the components individually AND/OR as a group.

IE: waterskis and waterski bindings sold both individually, AND as a group or package at a lower price.

Hi there, Kristin.

I can see that there are multiple posts with similar questions about building an assembly. One of my colleagues has already responded to one of it and shared steps.

Let me share this link so you can read and follow the steps: https://quickbooks.intuit.com/learn-support/en-us/other-questions/re-available-inventory-for-group-o...

The Community is always here to help if you have other questions for us.

You have clicked a link to a site outside of the QuickBooks or ProFile Communities. By clicking "Continue", you will leave the community and be taken to that site instead.

For more information visit our Security Center or to report suspicious websites you can contact us here