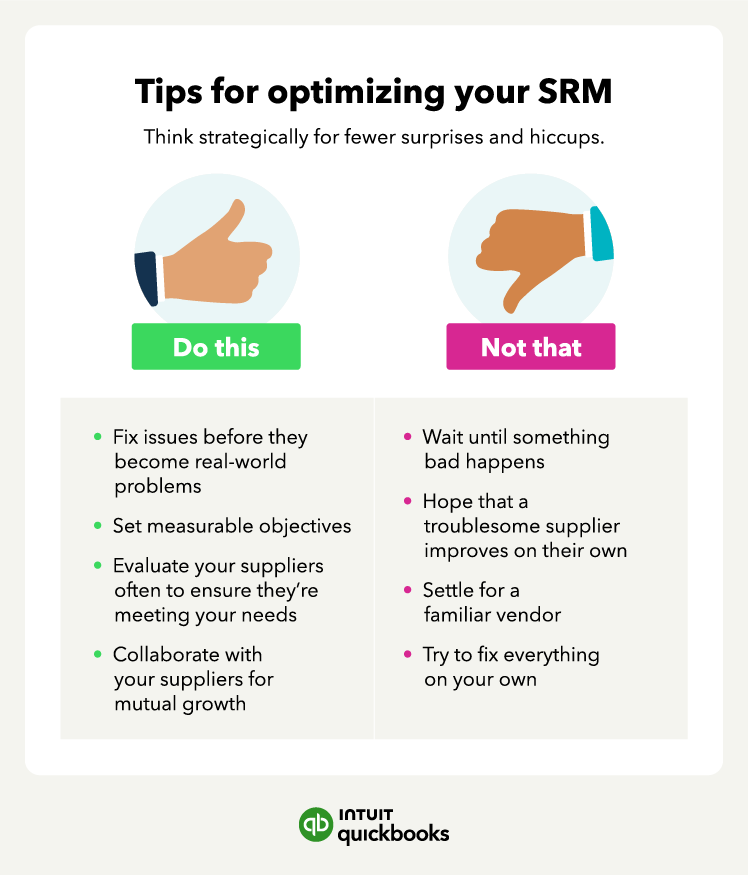

There are two kinds of SRM: reactionary and strategic. Most businesses won’t prioritize SRM until something bad happens, and they need to take a closer look at how their suppliers function. This is reactionary SRM. If you have to use reactionary SRM, you should continue to examine and improve these systems to avoid problems in the future.

Strategic SRM is when you optimize processes involving vendors before problems arise. While this might not be possible for everyone, if you’re getting ready to expand into a new market, launch a new product, or you’re trying to figure out the most accurate inventory forecasting possible, you could begin thinking strategically to anticipate and fix issues.

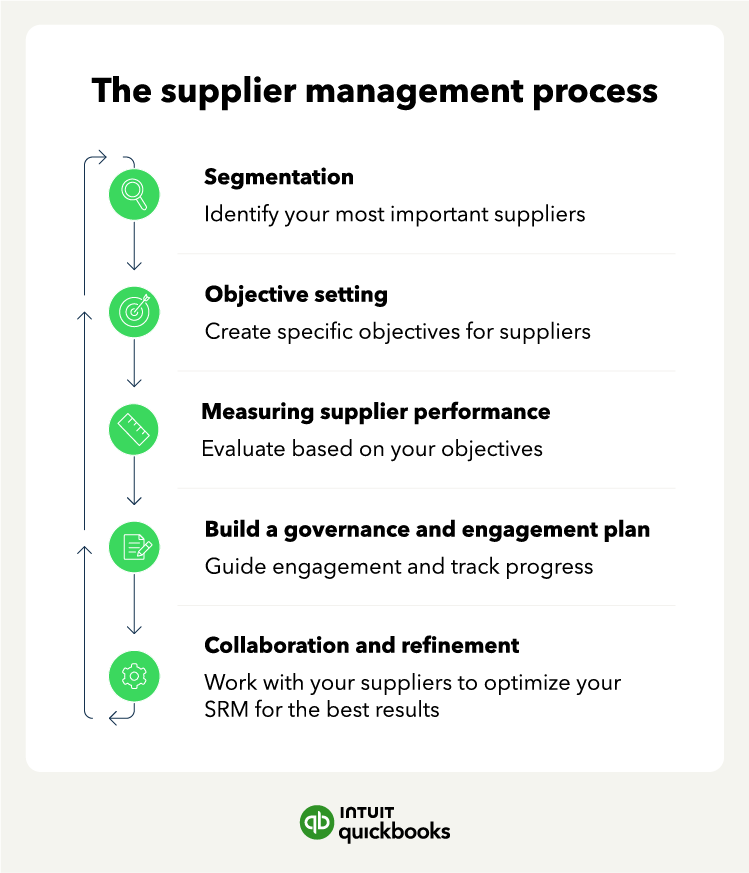

Whatever kind of SRM process you’re in, the overall structure of it remains the same.

Segmentation

Segmentation is the process of examining your suppliers and figuring out which ones are most important to your business. Once you build these segments out, you can prioritize the most important ones. Focus on the suppliers and segments that are critical to the success of your business and those most likely to cause problems.

Set objectives

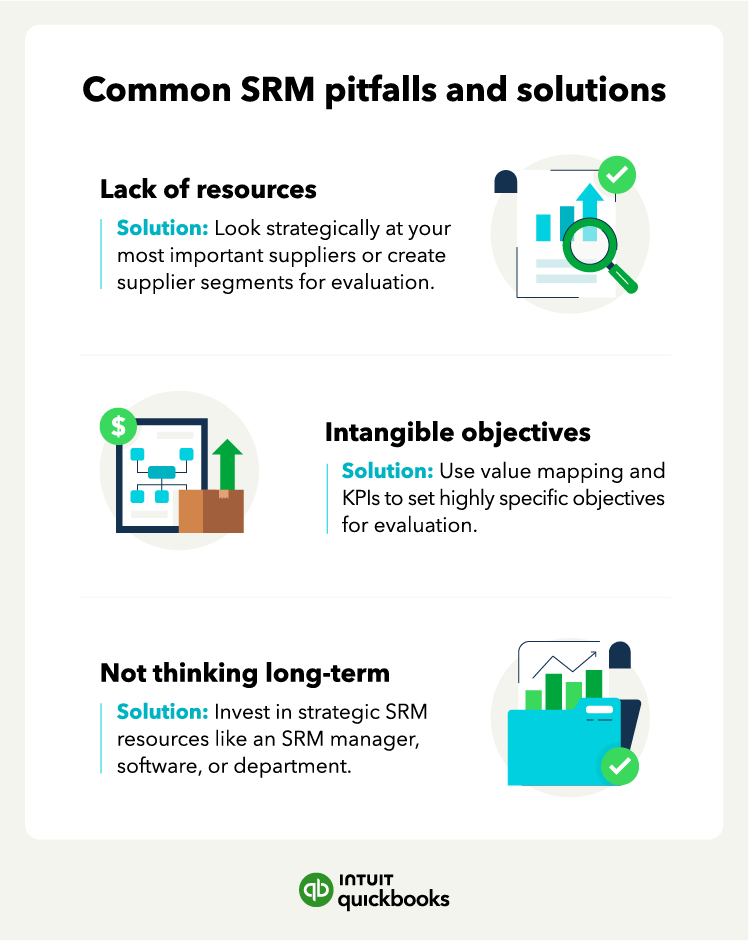

Setting objectives is one of the most critical parts of this process because it helps your company decide where to focus efforts, down to the most minute details. Once you set these objectives, you can measure supplier performance against them.

Establishing your objectives can be a long process, but there are a few good places to start:

- Start with the problem and work backward: If late deliveries are the problem, set a benchmark that you’d like to see the supplier meet. Then look back at the process and identify any areas that could indicate earlier delay. You can set an objective saying you want to receive a status report every two weeks before shipping to ensure things are on schedule.

- Read the contracts you’ve signed with the supplier: Your contracts should lay out expectations and what happens if those expectations aren’t met. If a service level agreement (SLA) doesn’t work for your business now, change them during an upcoming renewal.

Your objectives should include exactly how you will measure and evaluate your suppliers. These KPIs should help your team calculate how and where suppliers succeed or fall short. Using a scale is usually more helpful than a simple pass-fail system (though some metrics may be that clear), so work with your team to find a spectrum to place suppliers on.

Measure supplier performance

Now that you have your objectives, it’s time to look at your suppliers and see how they perform. If you’re in a reactionary SRM cycle, you’re probably seeing a lot of problems (or at least one big one). That’s OK – it’s why you’re doing this.

To get the clearest picture of vendor performance, you’ll probably need to talk to stakeholders in your own company and your supplier points of contact. Get all of the information you need to accurately compare vendor performance based on your newly developed objectives.

You may need to delegate performance tracking to team members who understand those vendors best. This might mean extra training to help them understand what supply chain KPIs they’re measuring and how you want that information formatted and delivered.

Measuring performance can be one of the most complex parts of SRM because of the number of factors that contribute to how a vendor performs. The better you understand how, where, and why a supplier is failing to live up to expectations, the better your governance and engagement plan will be.

Create a governance and engagement plan for suppliers

This part of the SRM is both internal and external. The internal part helps your team develop standards and processes for ensuring that deviations (late shipments, lower-than-promised quality) are properly tracked and reported. With specific and measurable standards, problems will be identified (and corrected) sooner than if you waited for an issue to bring production to a halt.

The governance plan is the external-facing set of guidelines your organization creates to ensure that a supplier meets the expectations agreed upon in conversations and contracts. This should include:

- Changing or updating contractual terms and conditions, including SLAs, to align with your company's objectives. You should anticipate some back and forth with your vendors to hammer out an agreement.

- Talking to your suppliers more frequently to find ways to mutually improve the relationship. Remember, your main suppliers rely on your business just like you rely on it.

- Flexibility within the plan. Use supplier feedback to help make changes that set everyone up for success while keeping everyone accountable.

An engagement plan means optimizing communication with your supplier and finding ways to learn more about your supplier to better understand how their process works in regard to your business. Regular supplier surveys and interviews can help you learn more about how they function, what their priorities are, and how your company can better interact with them.