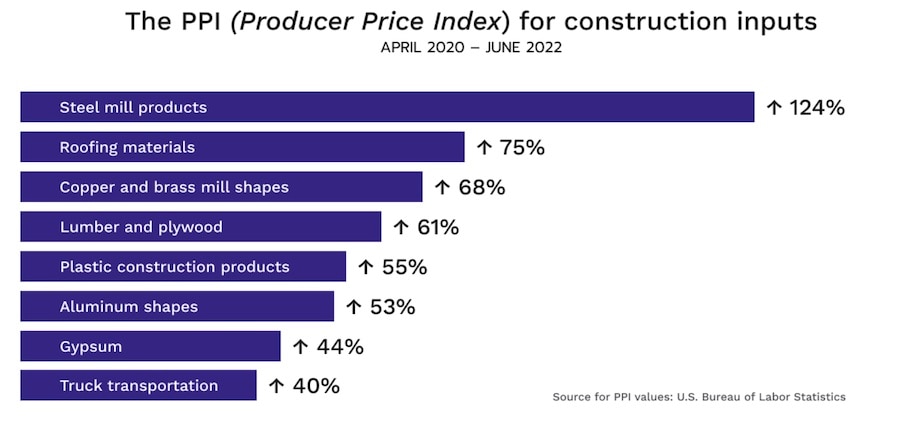

After a few tumultuous years, the construction industry is looking at a situation it hasn't quite seen before. Labor shortages, long lead times, cost escalations, and supply chain issues are all happening at the same time. It’s a perfect storm for historic inflation rates.

The annual construction input inflation rate in 2021 came in at 19.6%. By year's end, 2022 is expected to see a 14.1% increase. To put those numbers in perspective, the nonresidential construction inflation rate in 2019 was just 1.8%. In June 2022, rates reached 9.1% — a rate so high that it hasn’t been seen in almost half a century.

Rates have slowed down as of September 2022 (falling to 8.2%); the market appears to be correcting, albeit slowly. In the meantime, contractors need to understand two things: how we got here and what they can do to shield their businesses from the effects of inflation. We’ll start by looking at the main factors causing construction inflation.

What is causing construction inflation?

Global pandemic

COVID shutdowns in February 2020 brought factories in China and Italy to a halt. Shortly thereafter, many factories in the EU and the US shut down as well. The resulting lack of supply and unchanged demand from the market meant the cost of residential building materials had nowhere to go but up. In fact, costs increased by about 19% during the pandemic, according to the National Association of Home Builders (NAHB).

Compounding this issue is the United States' heavy dependence on imported building materials. A typical home in the US is built using an estimated 40% of imported materials. With a lack of supplies and high costs, many projects were delayed, resulting in an even larger backlog of work nationwide.

Continued labor shortage

Extending a decade-old trend, the industry continues to see job openings far exceed the number of hires. There are roughly 25% more unfilled construction positions than new hires. Unfortunately, firms are not in a position to downsize. In fact, job openings increased by 29% from 2021 to 2022. A high volume of delayed and upcoming projects means firms are in need of skilled labor now more than ever.

Companies are struggling to fill positions, but this isn't for a lack of trying. Many companies are raising wages and upgrading their benefits packages to better appeal to new hires. Incentivizing more workers to join the industry will help ease the situation, but it will bring its own set of challenges. Increasing labor prices will cut into margins at an already uncertain time.

Unexpected global events

Adding fuel to the fire, a series of global "one-off" events served as a tipping point for the historic inflation rates that we see today. The blockage of the Suez Canal in March of 2021, for example, disrupted an astonishing 12% of the world's global trade. The intensifying conflict in Ukraine is another recent example. Trade restrictions imposed on Russia have limited the supply of many materials, including crude iron, semiconductors, and ceramic tile.

Meanwhile, the United States has seen severe weather events, such as wildfires in California, an energy crisis in Texas, and hurricanes along the coasts. The year 2022 was one of the costliest hurricane seasons in US history, culminating with Hurricane Ida.

Events like Ida saw massive recovery efforts, rerouting materials, trucks, and workers. Combined with an already extensive backlog of projects, materials became even more scarce. Flooring, roofing, plumbing, and electrical supplies all experienced significant price increases as a result.

Low supply, high demand

Through it all, demand for builders and specialty contractors has remained remarkably high. Delayed projects are starting up again. A historic housing shortage means houses can't be built fast enough, and a rebuild of the nation's infrastructure is underway. Year-to-date, total construction starts are 11% higher compared to 2021. As we have already seen, firms don't have access to the materials and labor they need to meet this demand. This situation has put the laws of economics into practice, resulting in historically high inflation.