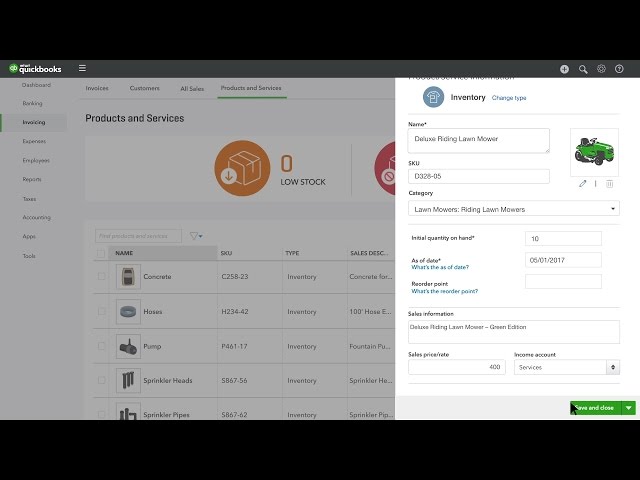

As products go down a manufacturing line, every added cost and inefficiency eats into the profit margin. But when dealing with inventory, you have to first take a step back before considering ways to streamline your production process.

There are many different types of inventory that move through the process, from raw materials to works-in-progress and, finally, a finished product. If you’re looking to understand and gain more inventory control this year, read on to learn the nine different types of inventory that exist.