Like any other business operation, maximizing cost efficiencies in manufacturing is key to ensuring the long-term success of your product. But for many businesses, striking a balance between product quality and low production costs is an ongoing struggle.

How to optimize your cost of production for simple manufacturing

With so many variables to consider – including raw materials, processes, labor costs, profit margins, and more – maintaining a reasonable cost of production isn’t an easy feat, but it is a necessary one. With that in mind, here are four key points to consider for manufacturing cost reduction.

1. Optimize your processes

Instead of looking at production cost on its own, you need to look at your entire manufacturing process. Many manufacturers find that focusing on process rather than on product or product-related costs is an initial important departure from standard practice. Looking at overall processes helps to manage the whole workflow and not just a part of it. Avoiding partial process optimization or the risk of improving part of a process while damaging is another.

Once you’ve looked at your entire production cycle from end to end, you might discover that a few tweaks is all that’s needed to bring down costs, or you might find that a complete overhaul is necessary. For example, contrary to perceived wisdom, it could actually be more cost-efficient for you to manufacture in-house and control your entire manufacturing workflow rather than use a third party. Whatever the case may be, making sure your processes are as efficient as possible is the first step to getting on top of your manufacturing costs.

2. Cut your material costs

One of the most obvious ways you can save on manufacturing costs is to cut down on your material costs. It’s common for new manufacturers to choose product components without fully understanding the cost implications, resulting in material cost blow-outs further down the line.

Consider reducing your raw material costs by tweaking the design of your product/s and/or seeking out cheaper alternative materials. Keep in mind, though, that you don’t want to use cheaper materials at the expense of product quality. Also make the most of leftover materials by reusing them in other products if possible or reselling materials like cardboard, paper, and metal.

3. Improve workforce productivity

Your staff are arguably your most important assets, but they’re also expensive. Look at ways your team can work more leanly to get tasks done faster without hindering accuracy. You can incentivize productivity through initiatives like:

- Performance accountability – driving productivity through active performance management

- Bonuses – incentivizing employees with bonuses could still be cheaper than paying overtime and other staff expenses

- More efficient work schedules

Aim for a demand-calibrated approach rather than a capacity-utilization approach to your workforce – which is to say, only utilize staff when you need them and scale employee numbers up or down as needed.

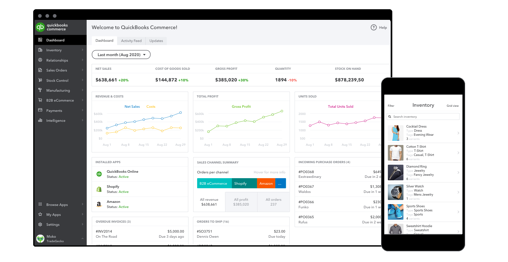

4. Consider your inventory carrying costs

Storing inventory for a long time – whether it’s finished products or raw materials – can quickly become very expensive. As a manufacturer, consider your overall inventory carrying costs, including the cost of storage, insurance, maintenance, and disposal if applicable. Having an optimized production process will help avoid overproduction and reduce excess storage costs.

Smart demand forecasting also helps ensure you’re manufacturing on an “as-needed” basis i.e. responding directly to customer demand rather than leaving your production schedule to guesswork. If you have a highly accurate picture of future demand and a trusted relationship with materials suppliers, you could even take a Just in Time approach to manufacturing to keep your holding costs as low as possible.