For commerce businesses, manufacturing lead times are an important consideration when it comes to optimizing your replenishment process, using resources efficiently, and keeping stock and production moving as efficiently as possible. The shorter your lead time, the more effectively you can run your business – so here’s everything you need to know about manufacturing lead times: what they are and how to reduce them.

Why reducing manufacturing lead times is vital for your business

What are manufacturing lead times?

Your lead time is the amount of time it takes for you to receive stock from a supplier– that is, the time between ordering stock and meeting anticipated sales demand to avoid going out of stock. It’s why strategically designating your reorder point and safety stock levels are important. For instance, if you waited until all your stock was sold, there would consequently be a gap as you ordered and awaited shipment of the next lot of stock.

A long gap between ordering stock and having it arrive could potentially result in customers who are unable to order product when they want, possibly leading them to opt for a competitor. It could also result in poor use of resources, as staff wait around while the shipment arrives.

Of course, there’s also the complicating factor that different manufacturing partners and suppliers will have different lead times for different products and order sizes, so it can get tricky to manage different lead times concurrently.

Why is it important to reduce lead time?

Reducing lead time is a profitable aim for commerce entrepreneurs. Not only does a shorter lead time mean less time spent waiting for stock to arrive, but it also allows for greater flexibility. Retailers can order according to market demand and fluctuations: if a product that takes a month to arrive suddenly goes out of favor with consumers in the second week of lead time, you have to figure out what to do with it two weeks later when a shipment arrives – and it often ends up as dead stock in your warehouse.

However, if you’re ordering smaller shipments on a weekly rolling basis, you can be nimble and flexibly react to the market.

How can you reduce manufacturing lead time?

Lead time is partially a function of your order management system and how you communicate your orders with your suppliers, and partially the time it takes for suppliers to fulfil the order. That being said, in order to reduce it, you’ll need to work from both ends and get buy-in from your suppliers. Here are some tips for reducing lead times:

- Order smaller amounts more frequently. Larger orders take longer to fulfil and ship. Producing stock on a more regular, rolling basis helps not only with the agility of the retailer to meet market need, but also for the manufacturer to quickly produce and ship stock.

- Have a clear lead time contract. Part of your standard contract with every supplier should be a clear undertaking of lead times with penalties stipulated for late shipments and damaged goods, as well as advance warning of any changes to stock lines in terms of price, availability and discontinuations.

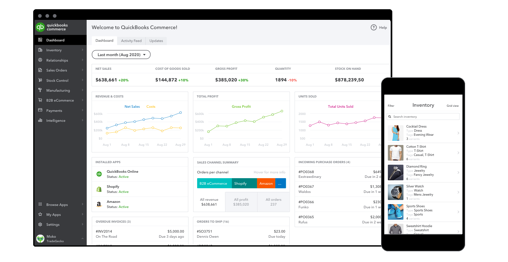

- Automate your inventory management. Juggling multiple suppliers’ lead times via a manual spreadsheet will only increase the risk of human error and missed orders, so you can eliminate significant admin and risk by using an inventory management system that can automatically create an order when stock reaches reorder point.

- Let your supplier know about sales data. In today’s world, businesses who treat their suppliers as partners often come out ahead. For example, sharing sales data with manufacturers means that they can see what’s popular and even anticipate your needs, getting ahead of an order before it’s even made. This can hugely reduce lead time as production is already happening before the order has been put in.

QuickBooks Commerce's inventory management software automates almost every manual process in the stock monitoring and order management process, and can also integrate with your supplier to more easily communicate, reducing lead times and improving product quality.