Effective demand forecasting and demand planning are key to the longevity of wholesale and retail businesses alike. We look at some of the major aspects of the demand planning process and how they impact the entire supply chain.

.jpeg)

The definitive guide to demand planning

What is demand planning?

Demand planning is a supply chain management technique by which businesses analyze historical sales data to create reliable forecasts of future demand. This not only allows businesses to plan for upcoming trends, but also to evaluate the success of past decisions, creating a continuous cycle of review and refinement.

Demand planning helps businesses:

- Improve the accuracy of revenue forecasts

- Optimize inventory according to peaks and troughs in demand

- Maximize profitability from each sales channel or product

- Minimize warehousing and inventory holding costs

- Reduce the need for safety stock

- Effectively manage distribution networks

- Make data informed decisions about sales and marketing strategies

- Expand into new markets or countries

- Respond quickly to changing market conditions

In other words, the ability to generate a precise demand forecast has a major impact on virtually every area of a business.

The quality of the forecast is important too: even a minor improvement in forecast accuracy can have a ripple effect across a business, reducing inventory buffers, dead stock, and unnecessary manual labor, whilst maximizing supply chain efficiencies. These improvements help drive greater customer satisfaction, and ultimately, higher profitability.

The demand planning process in a nutshell

Demand planning workflows look slightly different from business to business, depending on the individual needs of a company and how it operates. Generally speaking, though, the process is as follows:

- Import historical sales data – Using a demand planning system, the business creates a central repository for sales data, which will form the basis for their demand forecast.

- Create a demand forecast – An initial forecast is generated using a demand planning tool that analyzes the historical data.

- Utilize other data sources – Customer feedback or other data sources are analyzed to help inform demand planning strategies.

- Create a consensus forecast – A demand forecast is created taking into account multiple data sources e.g. historical sales data, customer feedback, etc.

- Align forecast with business decisions – Tactical decisions about resources, inventory, distribution, shipping, and so on are made based on the demand forecast.

- Ongoing adjustments to the plan – As more data becomes available, tweaks to the formula are made to meet demand on an ongoing basis.

This process turns data into insight, enabling teams to discover and plan ahead based on fact rather than guesswork.

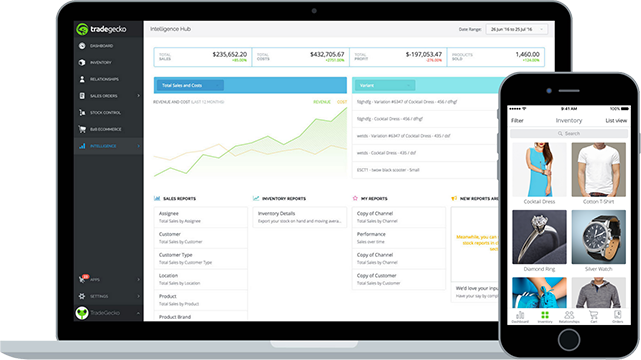

Demand planning made simple with TradeGecko

From reducing costs to keeping consumers happy, demand forecasting is an essential element of inventory planning and management. TradeGecko’s new demand forecasting functionality uses historical data to pull out insights into future demand by product, variant, warehouse location, etc. so you can plan accordingly.

The system also triggers automated inventory alerts with recommended reorder quantities based on automatically forecasted sales demand. This means you can order stock at the right time and in the right quantities, minimizing capital risk and maximizing customer satisfaction.