Examples of supply chain strategy in action

Companies of all sizes face supply chain challenges. Let’s look at real-world examples of companies that were able to improve and optimize their supply chain with effective strategies:

Walgreens leans into big data

Walgreens started investing in supply chain technology that aggregates data to improve efficiency. Historical inventory and sales data helped Walgreens adjust its supply chain to reduce excess inventory and cut costs for warehousing and transportation. They also ensure they have enough stock to meet expected customer demands.

Bob’s Discount keeps tabs on tariffs

The furniture retailer Bob’s Discount Furniture kept a pulse on higher tariffs on goods sourced from China—which would directly impact their business. In response, they shifted their furniture sourcing out of China.

Boeing navigates digital thread

Boeing adopted a digital thread strategy to navigate its vast parts supplier network. Its digital thread allowed it to track assets and connect data from design, manufacturing, and supply chain operations. This allowed for real-time visibility and collaboration, improving manufacturing processes and streamlining aircraft assembly.

Eaton adds sustainability

Eaton recognized the growing importance of sustainability in its supply chain. The company launched an initiative to reduce its carbon footprint and improve energy efficiency. As part of its supply chain strategy, it collaborated with suppliers to implement eco-friendly practices and transparent reporting.

Intel builds in resilience

Intel faced supply chain disruptions during the global chip shortage. However, the company's proactive approach to risk management, including diversifying its supplier base, has allowed it to navigate the crisis relatively well. Intel's resilience demonstrated the importance of preparedness and agility in the face of unforeseen challenges.

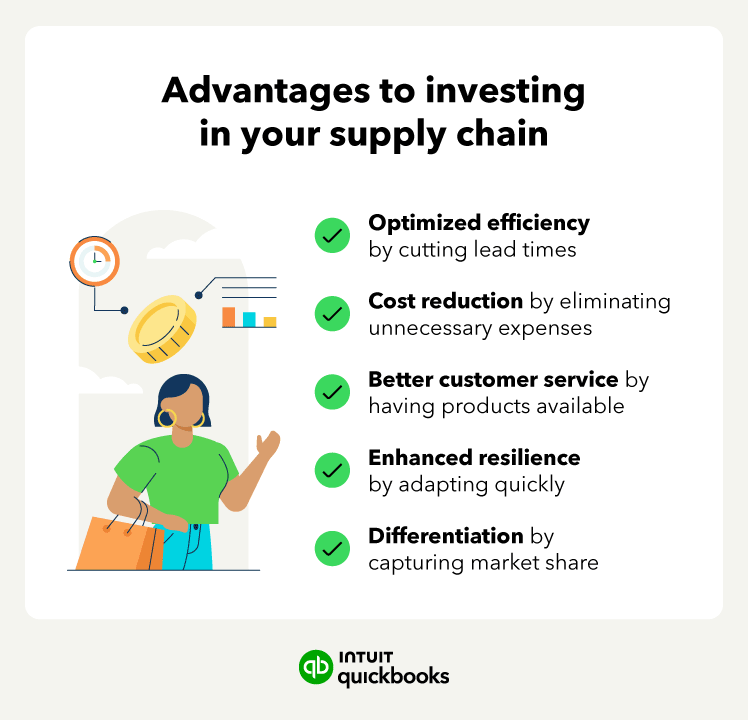

Benefits of supply chain management

Supply chain management is a strategy that gives organizations a competitive advantage. Here are the top advantages of putting a supply chain strategy in place:

- Better efficiency: Tailoring supply chain processes to specific business needs streamlines operations, eliminates waste, and reduces lead times, driving a substantial increase in overall productivity.

- Lower costs: Better efficiency starts with precisely identifying and eliminating unnecessary expenditures, resulting in leaner, more profitable operations.

- Improved customer satisfaction: Aligning the supply chain with customer expectations ensures products are consistently available at the right time and place.

- Increased resilience: A flexible and adaptable supply chain enables swift responses to market fluctuations and unexpected disruptions.

- Competitive advantage: Excelling in areas that matter most to their business, companies can differentiate themselves from competitors and gain capture market share.

Set specific, quantifiable, and time-bound goals for your supply chain strategy, like reducing total supply chain costs by 10% within two years or increasing

Set specific, quantifiable, and time-bound goals for your supply chain strategy, like reducing total supply chain costs by 10% within two years or increasing

Increasing your supply chain’s resilience may not be particularly cost-effective in the short term, but it can ensure long-term profitability.

Increasing your supply chain’s resilience may not be particularly cost-effective in the short term, but it can ensure long-term profitability.