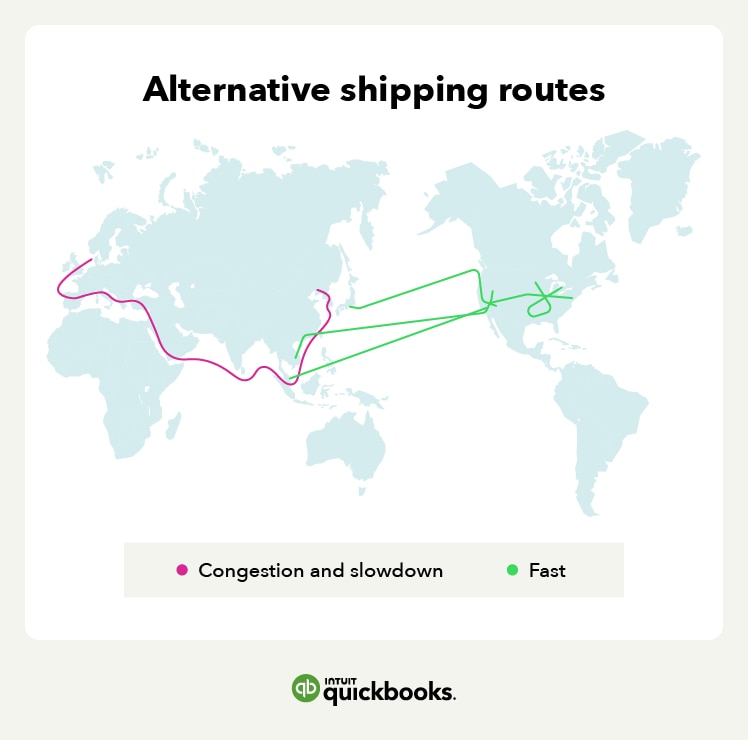

While small businesses can’t end shipping issues in Europe, they can plan around them. Instead of relying on central shipping routes in this area, companies should buy from suppliers who take alternate channels. Alternatively, they can buy more expensive goods produced closer to the U.S.

While these solutions cost more up-front, you won’t risk losing as many customers over indefinite delays and a shortage of products.

3. Logistical issues

Ports, trucking companies, and factors are all overwhelmed. For the best ROI, these businesses perform a careful balancing act. They simultaneously have to meet consumer demand while not exceeding operational capacity. But when one or more points in a supply chain experience instability, this delicate balance shifts.

Cause: Manufacturing and shipping changes

Adjusting to dramatic supply chain changes is never easy. Not only are companies’ operations planned far in advance, but old logistical models won’t help businesses adapt to new problems. On top of that, reliably measuring future supply and demand requires shipping and production information currently subject to change.

In short, manufacturers and shipping companies don't have the logistical tools to predict or immediately solve supply problems.

Solution: Adopt an iterative approach

If large corporations struggle to make long-term supply plans, small businesses are in the same boat. So, companies must take a flexible approach instead of committing to one logistical strategy. Small businesses should use known factors in the short term to implement tentative strategies open to future adjustments.

On the one hand, some of these operational choices may not pan out. Conversely, keeping the door open to an iterative approach means they can course-correct if future issues come up. As an added bonus, an emerging marketing of supply chain companies formed to help businesses redefine their long-term strategy.

4. Labor shortages

The U.S. has seen record drops in warehouse workers, truck drivers, and shipping employees. Across these industries, hundreds of thousands of jobs are left unfilled. These gaps in the labor force exacerbate an already damaged supply chain.

Cause: Poor working conditions

Many shipping and warehouse jobs pay a relatively low wage. Pair these low paychecks with rising inflation, and it’s no surprise why many workers decided to leave their positions to earn higher salaries elsewhere. Additionally, the recent pandemic left employees in these industries at higher risk of contracting COVID.

Solution: Invest in your labor force

In addition to valuing your employees, work with companies that pay their workers a fair wage. Higher employee salaries may correlate with a higher price to do business with one shipping or manufacturing partner. However, if your suppliers have well-paid workers, they're less likely to see employee dropoff.

Working with a low-cost company is tempting, but supply chain issues mean small businesses need reliable partners. By storing and shipping goods with teams that pay a high wage, you will find secure relationships with other companies in a sustainable supply chain.