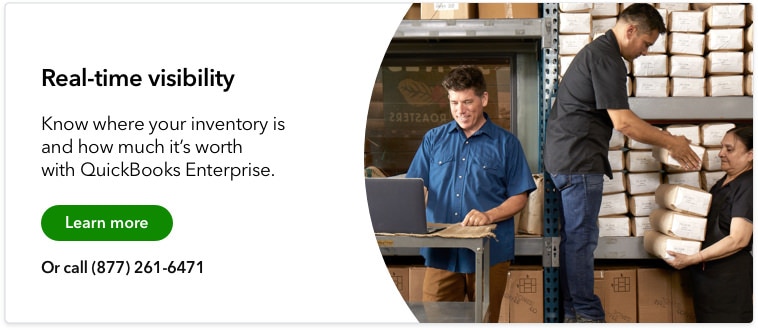

For any business that sells physical products, inventory is a critical asset, and how it’s managed plays a big role in business profitability. Businesses must have an inventory management system that gives them a clear picture of the number of items available at each location in real-time to fill orders efficiently and cost-effectively. Without accurate inventory records, a business is likely to experience poor order fill rates, shipping delays, bloated inventory costs, and even permanent business loss.

Businesses have traditionally conducted a physical count—a large undertaking to count the entire inventory of a warehouse location. Many companies consider it good practice to conduct a physical inventory count annually or bi-annually. A physical count is also required under certain tax and accounting regulations. But this method is time-consuming and complex, and usually requires the suspension of some operations.

To accurately track inventory levels in-between physical counts, businesses can benefit from conducting regular cycle counts—a targeted inventory counting technique to quickly measure stock levels without suspending business operations.