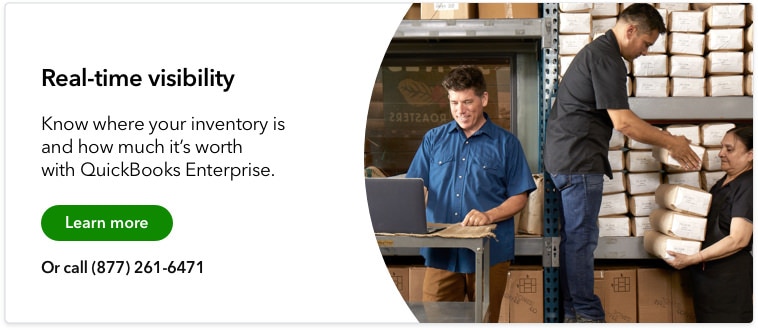

Warehouse management systems (WMS) help businesses monitor, optimize, and scale their warehouse or distribution center’s day-to-day functions. This technology provides real-time visibility into inventory status from when it arrives at the warehouse to when it’s shipped and delivered.

As businesses today manage more SKUs, longer shipping distances, and more extensive warehouses, warehouse management systems are becoming an increasingly attractive (and cost-effective) resource to improve their supply chain management—and there’s data to back it up.

According to Westernacher Consulting, most companies that switch from a paper-based system to an automated WMS software see a 25% gain in productivity, a 10-20% improvement in space utilization, and a 15-30% reduction in safety stock.

Considering the potential of WMS systems to improve warehouse operations, it’s crucial to understand how this software works and what you can expect if you decide to implement it.